Case Study

Optimizing Industrial Heating & Reducing Diesel Consumption

Our TFMS solution helped a leading manufacturing client with critical production schedules implement a hybrid heating system, fully monitored online, reducing diesel consumption and improving safety.

Project Highlights

- ✔ The client’s diesel heating system consumed 600 liters per day with no control valves installed.

- ✔ Our expert team analyzed operational processes, heat requirements, and safety constraints to redesign the system within 15 days.

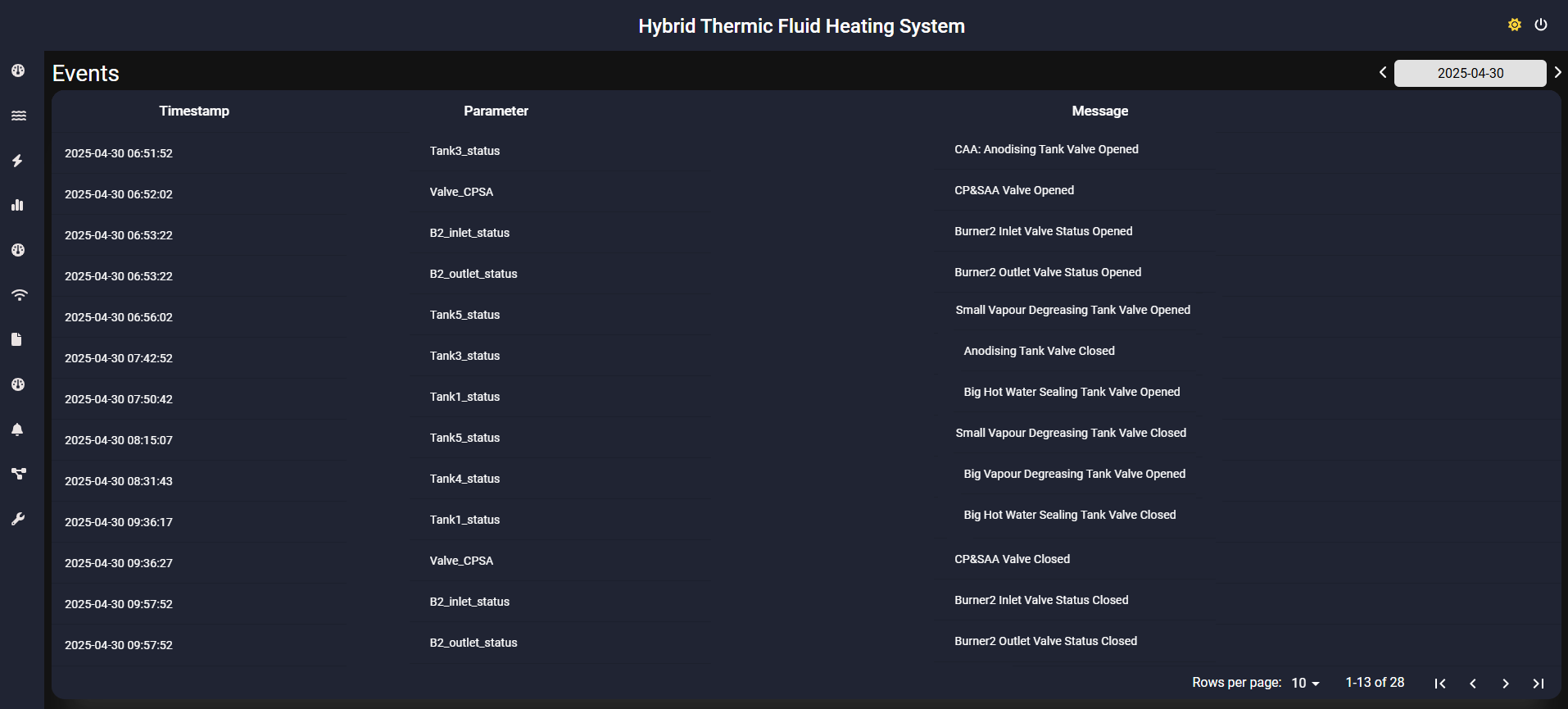

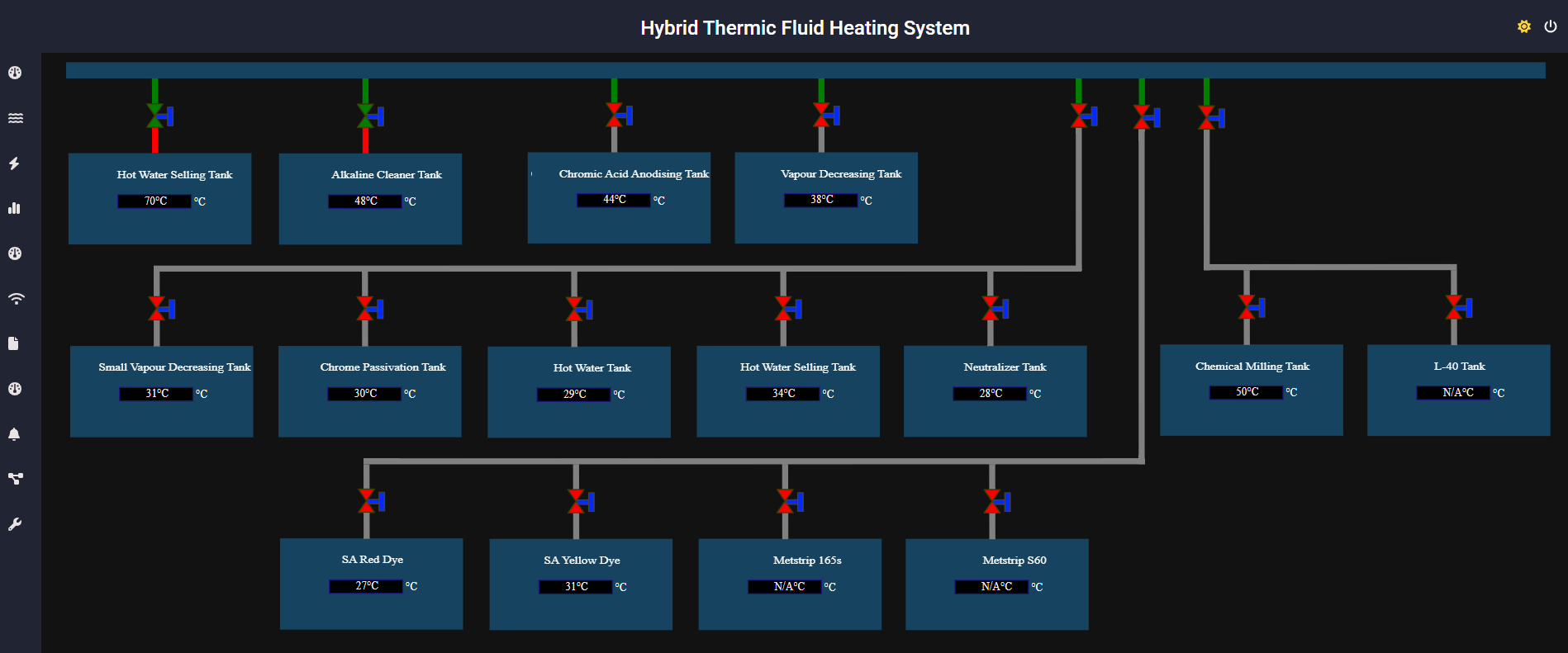

- ✔ Installed IoT-operated pneumatic valves for automated flow control and safety cut-offs.

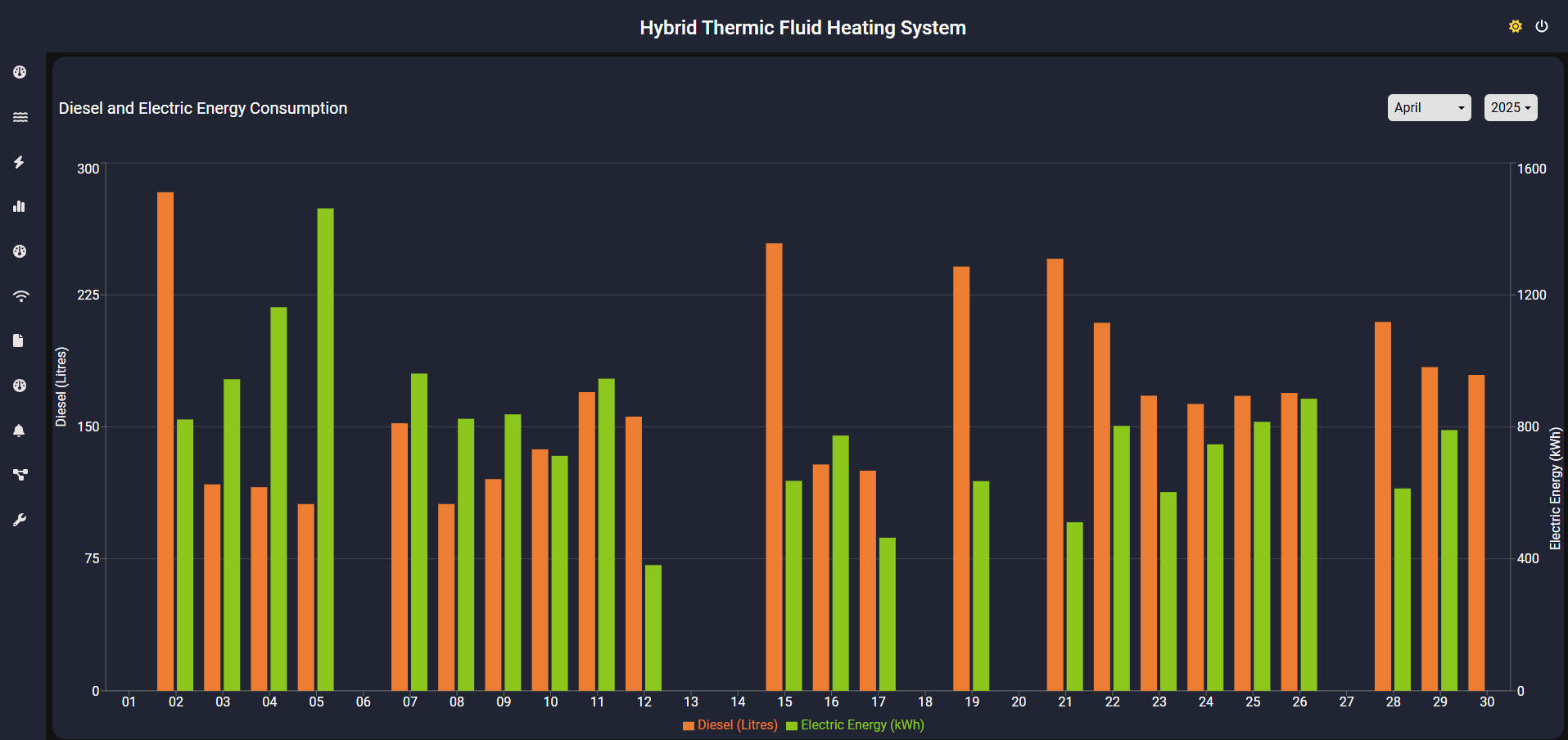

- ✔ Integrated a 4 Lakh kCal electric heater to create a hybrid diesel-electric heating system.

- ✔ Full online monitoring of all production lines with temperature logging, alerts, and automatic valve cut-off.

- ✔ Modified entire heating system to work safely in hybrid mode, adhering to industrial safety standards.

- ✔ Reduced diesel consumption, smoke emissions, and diesel transport requirements on-site.

- ✔ Enabled complete visibility and control for critical production schedules while improving energy efficiency.

Result: The client experienced optimized heating operations, reduced fuel costs, improved safety, and enhanced operational monitoring—contributing to higher revenue and environmental compliance.